Picture this: A single diamond worth $50,000 sitting on your cutting table. One microscopic measurement error, one tiny positioning mistake, and you’ve just turned that stone into expensive gravel.

I’ve been in enough diamond cutting facilities to see operators break into a cold sweat when their imaging system glitches during a critical cut. The stakes are that high. But here’s what I’ve learned after years of working with precision optics: the right lens system isn’t just equipment – it’s insurance for your most valuable assets.

Why Machine Vision Lenses Are Essential for Diamond Cutting Equipment

FA (Factory Automation) lenses provide precise positioning and alignment in diamond cutting workflows, while telecentric lenses deliver distortion-free measurement and cutting guidance with sub-micron accuracy. Together, they form the optical backbone that enables automated diamond processing worth millions.

But here’s what most people get wrong – thinking any precision lens will do the job. The truth is, diamond cutting requires a carefully orchestrated optical system where each lens type plays a specific, critical role.

The Two-Stage Optical Challenge in Diamond Processing

Let me break down what’s really happening in a modern diamond cutting operation, because this is where most people misunderstand the lens requirements.

Stage 1: Positioning and Workflow Management – This is where FA lenses shine. Before you can cut a diamond, you need to identify it, orient it correctly, and move it through various stations. FA lenses handle the broader view tasks: reading laser inscriptions, tracking stones through the production line, and ensuring proper positioning at each workstation.

Stage 2: Precision Measurement and Cutting – This is telecentric lens territory. When you’re measuring facet angles, positioning cutting tools, or guiding laser systems, you need the geometric accuracy that only telecentric optics can provide.

I’ve seen operations try to use standard machine vision lenses for both tasks, and it’s like using a hammer for surgery. Sure, it might work sometimes, but you’re gambling with incredibly expensive materials.

Why FA Lenses Handle the Positioning Workflow

Here’s something most diamond cutting facilities don’t optimize properly: the positioning and tracking workflow that happens before any cutting begins.

Diamond Identification and Sorting: FA lenses excel at reading laser inscriptions, analyzing inclusion patterns, and categorizing stones. Their standard perspective imaging is perfect for these broader identification tasks where you need flexibility and good overall image quality.

Multi-Station Positioning: As diamonds move through cleaning, initial assessment, and pre-cutting stations, FA lenses provide the consistent imaging needed for robotic handling and positioning systems.

Quality Pre-Screening: Before expensive telecentric measurement systems analyze a stone, FA lenses can quickly identify obvious flaws or determine if a stone is worth the detailed analysis time.

The key advantage? FA lenses are cost-effective for these broader workflow tasks, saving the expensive telecentric systems for where they’re absolutely critical.

How Telecentric Lenses Transform Measurement and Cutting

Now, when it comes to the actual measurement and cutting processes, this is where telecentric lenses become non-negotiable.

The measurement accuracy problem is something I see constantly. When you’re trying to measure precise angles and dimensions for optimal cutting, even tiny perspective distortions can result in incorrectly cut facets. I’ve worked with facilities that were losing 15-20% of their stone value due to measurement inaccuracies before switching to telecentric systems.

Cutting guidance precision is where telecentric lenses really prove their worth. Unlike FA lenses, telecentric lenses maintain the same magnification regardless of the object’s distance from the lens (within the working distance range). This means when you’re positioning cutting tools or guiding laser systems, you get consistent, reliable measurements every single time.

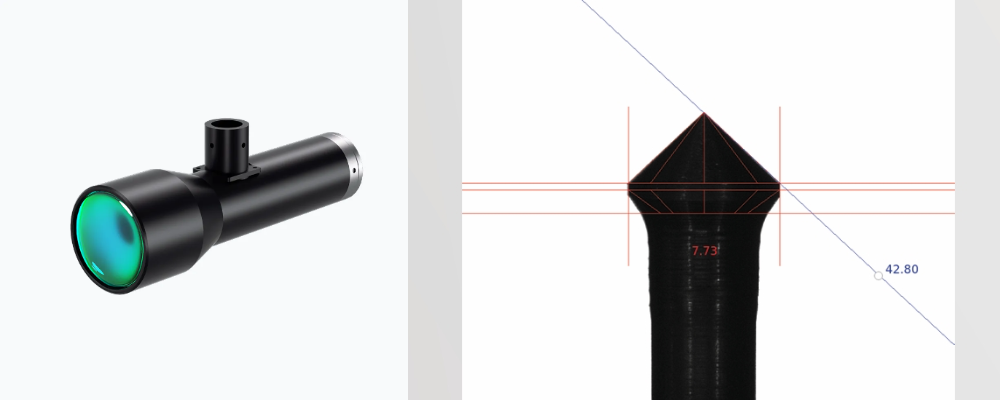

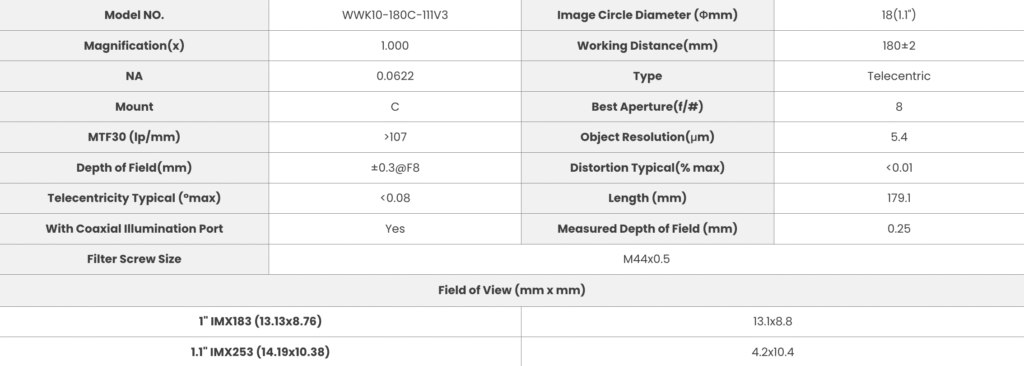

The COOLENS WWK10-180C-111V3: Purpose-Built for Critical Measurements

Let me tell you about a lens that’s specifically designed for the measurement and cutting challenges – the COOLENS 1.1″ 1X Telecentric Lens (WWK10-180C-111V3).

This isn’t just another industrial lens. Here’s what makes it essential for diamond cutting:

1X Magnification with 180mm Working Distance: This gives you plenty of room for cutting equipment while maintaining life-size imaging. In diamond cutting, you need space for laser heads, air flow systems, and safety equipment.

18mm Image Circle: Perfect for capturing complete views of larger diamonds or monitoring cutting progress across the entire stone surface.

0.06224 Numerical Aperture: This provides excellent depth of field, ensuring sharp focus across irregular diamond surfaces and facets.

Distortion-Free Geometry: This is the killer feature – measurements taken anywhere in the field of view are geometrically accurate, essential for precise cutting tool positioning.

Real-World Workflow Integration

Let me walk you through how these lens types actually work together in practice:

Step 1 – Intake and Positioning (FA Lens): Diamonds arrive and FA lenses handle identification, sorting, and initial positioning. These lenses read laser inscriptions, check for obvious flaws, and guide robotic systems that move stones to measurement stations.

Step 2 – Precision Analysis (Telecentric Lens): The WWK10-180C-111V3 takes over for detailed measurement. Facet angles, proportions, and optimal cutting plans are developed using the distortion-free imaging that only telecentric lenses provide.

Step 3 – Cutting Execution (Telecentric Lens): During actual cutting, telecentric lenses guide laser systems or mechanical cutting tools with micron-level accuracy. The consistent magnification ensures cutting paths are exactly where they need to be.

Step 4 – Final QC (Both Systems): FA lenses handle general quality checks and documentation, while telecentric systems verify critical measurements meet specifications.

Cost vs. Value: The Complete System Approach

Here’s the business case that convinced one of my largest clients to invest in both lens types:

They were processing about 300 carats per month. By optimizing their workflow with FA lenses and improving cutting accuracy with telecentric systems, they:

- Increased throughput by 25% (FA lens efficiency gains)

- Improved average stone value by $400 per carat (telecentric cutting accuracy)

- Reduced waste by 12% (better measurement precision)

The complete optical system paid for itself in six weeks.

FA Lens ROI: Faster processing, better workflow automation, reduced handling errors Telecentric Lens ROI: Higher stone grades, less waste, automated cutting capability

Integration Best Practices

Camera Matching: Ensure your cameras match each lens type’s capabilities. The WWK10-180C-111V3 needs a 1.1″ format sensor to utilize its full image circle.

Lighting Systems: FA lenses work well with standard illumination, but telecentric lenses need telecentric lighting for optimal results.

Software Integration: Your vision software needs to understand which lens type is being used for each measurement task.

Conclusion

Diamond cutting isn’t a single optical challenge – it’s a complex workflow requiring different optical solutions at different stages. FA lenses excel at positioning, identification, and workflow management, while telecentric lenses like the COOLENS WWK10-180C-111V3 provide the measurement accuracy and cutting guidance that determines your final stone value.

The key insight? Don’t try to force one lens type to do everything. Use FA lenses where flexibility and cost-effectiveness matter, and deploy telecentric systems where measurement accuracy is critical. This integrated approach maximizes both operational efficiency and cutting precision.

When you’re dealing with materials worth thousands per carat, having the right optical tool for each job isn’t just smart engineering – it’s the difference between profit and devastating loss.