After testing hundreds of vision systems over the past decade, I know that choosing the right calibration test chart can make or break your measurement accuracy. Whether you’re struggling with reflections, precision issues, or durability concerns, I’ll help you select the perfect material for your application.

What Are White PE, White Film, and Paper Calibration Test Charts?

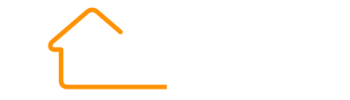

Calibration test charts are precision-engineered reference tools used to assess, calibrate, and validate imaging systems across various industries. They come in three primary material options:

White PE (polyethylene plastic) with black coating offering high durability and 30μm minimum line spacing; White Film with inkjet printing providing 0.3mm minimum features and backlight compatibility; and Photo Paper delivering high-contrast patterns with 0.3mm resolution in color or black/white.

Each material offers different optical properties, durability levels, and precision characteristics suited for specific imaging applications.

Keep reading to discover which material best suits your specific application, how to avoid common selection mistakes, and why the substrate choice matters more than many engineers realize.

Understanding Calibration Test Chart Materials and Their Properties

When I first started working with machine vision systems, I made the classic rookie mistake – assuming all calibration charts were created equal. After a frustrating week troubleshooting a precision measurement system, I discovered the cause: the paper chart I was using had warped slightly from humidity.

Let’s break down the three main materials to help you avoid similar issues:

| Term No. | White PE (Polyethene plastic) | White Film | Photo Paper | |

| Pattern Info | Production Process | Laser Drawing | Inkjet | Inkjet |

| Coating Type | Black Coating | Ink | Ink | |

| Minimum Line/Space | 0.05mm | 0.3mm | 0.3mm | |

| Feature Accuracy | ±10μm | ±0.1mm | ±0.1mm | |

| Glossy or Matte | Matte | Matte | Matte | |

| Coating Thickness | 5μm | / | / | |

| Colour | Black and White | Colour | Colour | |

| Substrate Info | Reflection Type | Diffuse Reflection | Transmission | Diffuse Reflection |

| Illumination Type | Front Light Illumination | Backlight Illumination | Front Light Illumination | |

| Thickness | 0.185mm (±0.01mm) | 0.22mm (±0.02mm) | 0.22mm / 300g (±0.02mm) | |

| MAX Size | Width: 1.5m Length: 2.68m | Width: 1.2m Length: 30m | Width: 1.6m Length: 30m | |

| Waterproof | Waterproof | Waterproof | Non-waterproof | |

| Adhesive on Back | Available | Available | Available |

White PE (Polyethylene Plastic)

White PE calibration charts are essentially durable plastic sheets with precision patterns applied through laser drawing and black coating. Think of them as the industrial workhorses of the calibration world.

Key specifications:

- Minimum line/space: 30μm

- Feature accuracy: ±10μm

- Production process: Laser drawing

- Thickness: 0.185mm (±0.01mm)

- Maximum size: 1.5m width × 2.68m length

- Waterproof: Yes

- Reflection type: Diffuse reflection

- Illumination compatibility: Front light

White PE really shines in harsh industrial environments where durability matters. The black coating offers extremely high contrast (reflectivity <5% at 400-1000nm) and the 5μm coating thickness provides excellent edge definition. I’ve had PE charts survive for years in manufacturing environments where paper charts would have been destroyed in weeks.

Figure L: Actual zoom in 400 times views, 60 sectors on PE.

White Film

White film charts represent the middle ground, offering better precision than PE but with good durability. They’re particularly valuable for backlit applications.

Key specifications:

- Minimum line/space: 0.3mm

- Feature accuracy: ±0.1mm

- Production process: Inkjet printing

- Thickness: 0.22mm (±0.02mm)

- Maximum size: 1.2m width × 30m length

- Waterproof: Yes

- Reflection type: Transmission

- Illumination compatibility: Backlight

The standout feature of white film is its translucent nature, making it ideal for transmitted light setups. I’ve used white film extensively for telecentric lens calibration and backlighting applications where light must pass through the chart.

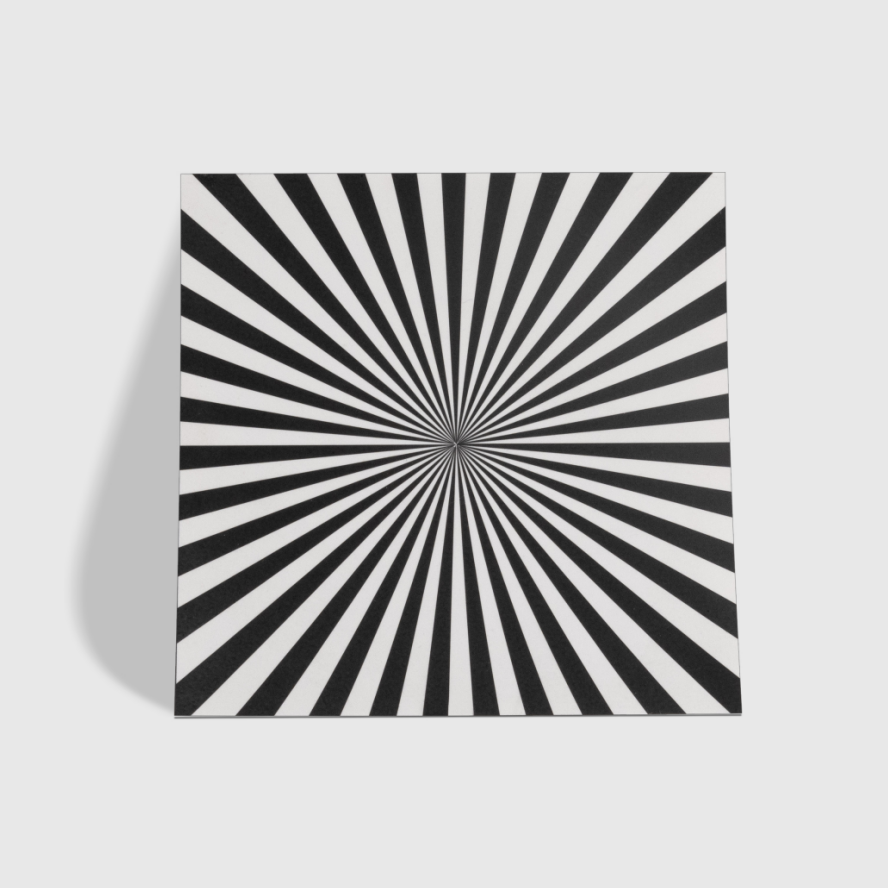

Photo Paper

Photo paper charts offer the highest resolution and color accuracy but sacrifice some durability.

Key specifications:

- Minimum line/space: 0.3mm

- Feature accuracy: ±0.1mm

- Production process: Inkjet printing

- Thickness: 0.22mm / 300g (±0.02mm)

- Maximum size: 1.6m width × 30m length

- Waterproof: No

- Reflection type: Diffuse reflection

- Illumination compatibility: Front light

Photo paper excels in applications requiring color calibration or very high contrast patterns. The matte finish reduces glare, making it perfect for controlled laboratory environments or color calibration tasks.

Choosing the Right Material for Your Application

The right chart material depends entirely on your specific application needs. Here’s my practical guide based on years of field experience:

When to Choose White PE

White PE is your best bet when:

- Durability is paramount – Factory floors, high-usage areas, or anywhere charts might be handled frequently

- Extreme precision is required – The ±10μm accuracy outperforms other materials

- You need very fine features – The 30μm minimum line/space is 10× better than film or paper

- Environmental challenges exist – Humidity, occasional liquid exposure, or temperature fluctuations

- Long-term stability matters – PE maintains dimensional stability over time

I recommend PE for most industrial vision systems, metrology applications, and any scenario where the chart will be handled regularly or exposed to less-than-ideal conditions.

When to Choose White Film

Opt for white film when:

- Backlighting is necessary – Film’s translucent nature makes it perfect for transmission lighting

- You need color patterns with backlighting – Film allows colored light to pass through

- Moderate durability is sufficient – More robust than paper but more flexible than PE

- You’re working with telecentric lenses – The transmission properties work well with these systems

- Large format is required – Available in lengths up to 30m

White film is my go-to for optical distortion measurement, telecentric lens calibration, and any application where light needs to pass through the target.

When to Choose Photo Paper

Photo paper makes the most sense when:

- Color accuracy is critical – Best for color calibration applications

- Controlled environment – Laboratory or clean room where durability concerns are minimal

- Complex patterns are needed – Supports intricate designs and color variations

- Budget is limited – Typically the most economical option

- One-time or infrequent use – When the chart won’t be handled extensively

I’ve used photo paper successfully for camera color calibration, laboratory research, and prototype testing before investing in more durable materials.

Illumination Considerations for Different Materials

The way you illuminate your calibration chart significantly impacts its effectiveness, and each material responds differently to various lighting techniques.

Front Light Illumination

Front lighting works well with PE and photo paper due to their diffuse reflection properties. When using front lighting:

- Position lights at 45° angles to minimize direct reflections

- Use diffuse lighting sources rather than point sources

- Ensure even illumination across the entire pattern surface

White PE performs exceptionally well with front lighting due to its matte surface and high contrast black coating.

Backlight Illumination

White film is specifically designed for backlight applications:

- Place the light source behind the chart

- Use diffuse lighting panels for even illumination

- Adjust brightness based on your camera’s sensitivity

The translucent nature of white film allows for excellent contrast in transmission mode, making features stand out clearly against the illuminated background.

Specialized Lighting Techniques

For the most demanding applications:

- Polarized lighting works well with white PE to further reduce surface reflections

- Structured light patterns can be projected onto white PE for 3D calibration

- Collimated lighting pairs effectively with white film for telecentric applications

Practical Durability Considerations

In real-world applications, durability often becomes the deciding factor. Here’s what I’ve observed after years of field testing:

- White PE charts typically last 3-5 years in industrial environments

- White film charts maintain their quality for 1-2 years with regular use

- Photo paper charts should be replaced every 3-6 months in active use scenarios

To maximize durability:

- Store charts flat in protective sleeves when not in use

- Keep spare copies of critical charts

- Handle only by the edges

- For paper charts, consider lamination (though this can affect optical properties)

- Control humidity for paper and film charts

Cost-Benefit Analysis and ROI

While initial costs vary (with PE typically being the most expensive and paper the least), the total cost of ownership tells a different story:

- A $300 PE chart that lasts 4 years costs $75 per year

- A $100 film chart replaced every year costs $100 per year

- A $50 paper chart replaced 3 times yearly costs $150 per year

For critical applications, the higher initial investment in PE often pays off through reduced replacement frequency and more consistent measurements over time.

Custom Configuration Options

Beyond the basic material choice, consider these customization options:

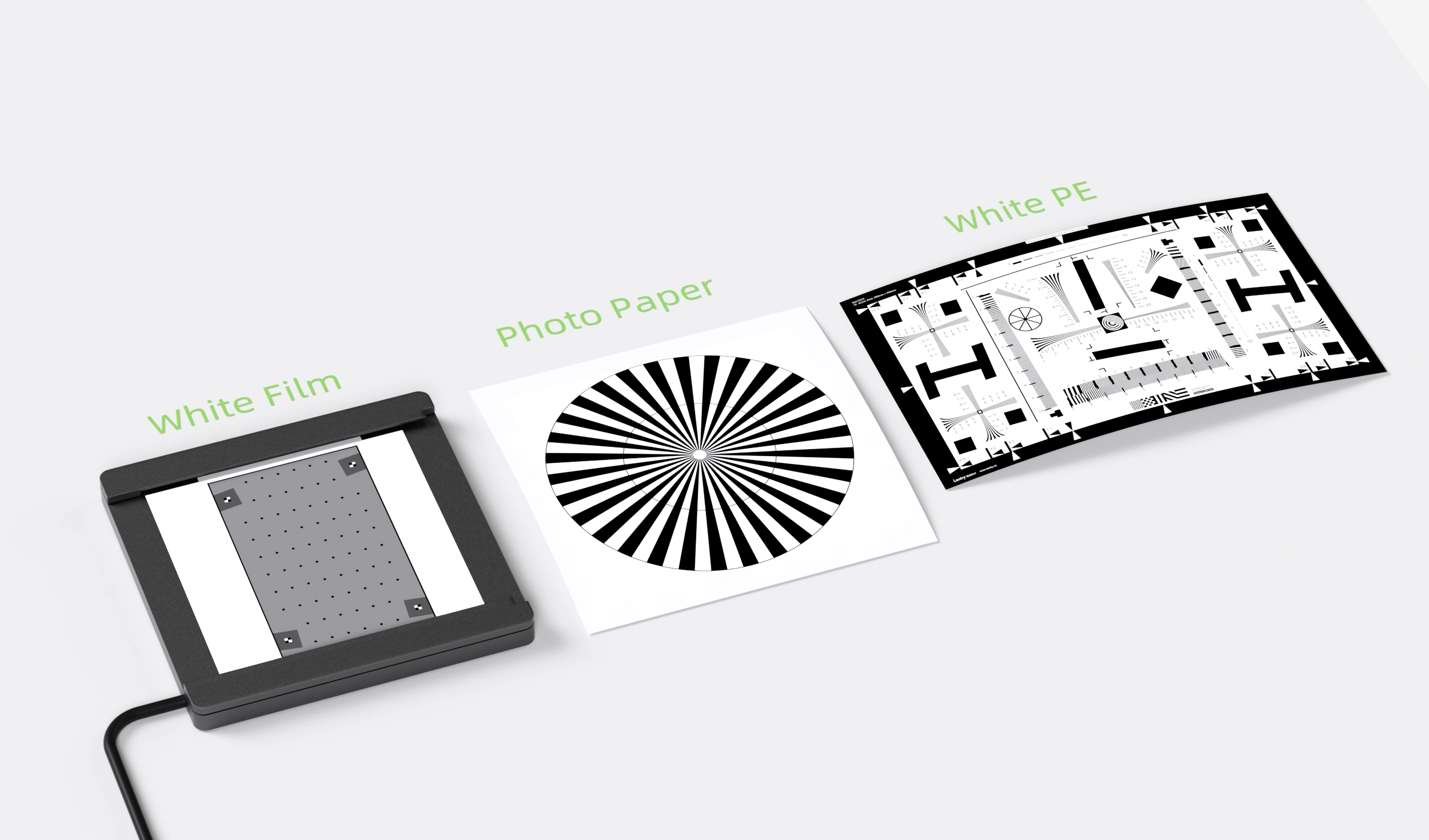

- Pattern selection – Standard patterns include checkerboards, dot arrays, Siemens stars, and resolution targets

- Adhesive backing – Available for all three materials for permanent mounting

- Custom sizing – All materials can be cut to specific dimensions

- Frame mounting – Rigid frames help maintain flatness, particularly important for film and paper

- Custom patterns – For specialized applications, custom patterns can be created on any material

Conclusion: Making the Right Choice for Your Application

When selecting a calibration test chart material, consider these key factors:

- Environment – Factory floor? Laboratory? Field work?

- Precision requirements – How accurate must your measurements be?

- Lighting setup – Front lighting, backlighting, or specialized?

- Handling frequency – Will the chart be regularly touched or moved?

- Budget constraints – Initial investment vs. total cost of ownership

For most industrial applications, White PE offers the best long-term value despite the higher initial cost. For backlit applications, White Film is often the only viable option. Photo Paper works well for controlled environments and color-critical applications.

Remember that even the most expensive vision system can only be as accurate as its calibration, making your choice of test chart material a crucial decision that impacts overall system performance.