I’ve been calibrating machine vision systems for over a decade, and I can tell you that choosing the right test target makes all the difference. Whether you’re setting up a new Halcon system or troubleshooting an existing one, the right calibration target will save you hours of frustration.

What Are Halcon Test Targets?

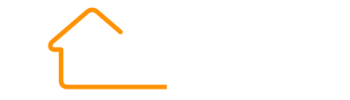

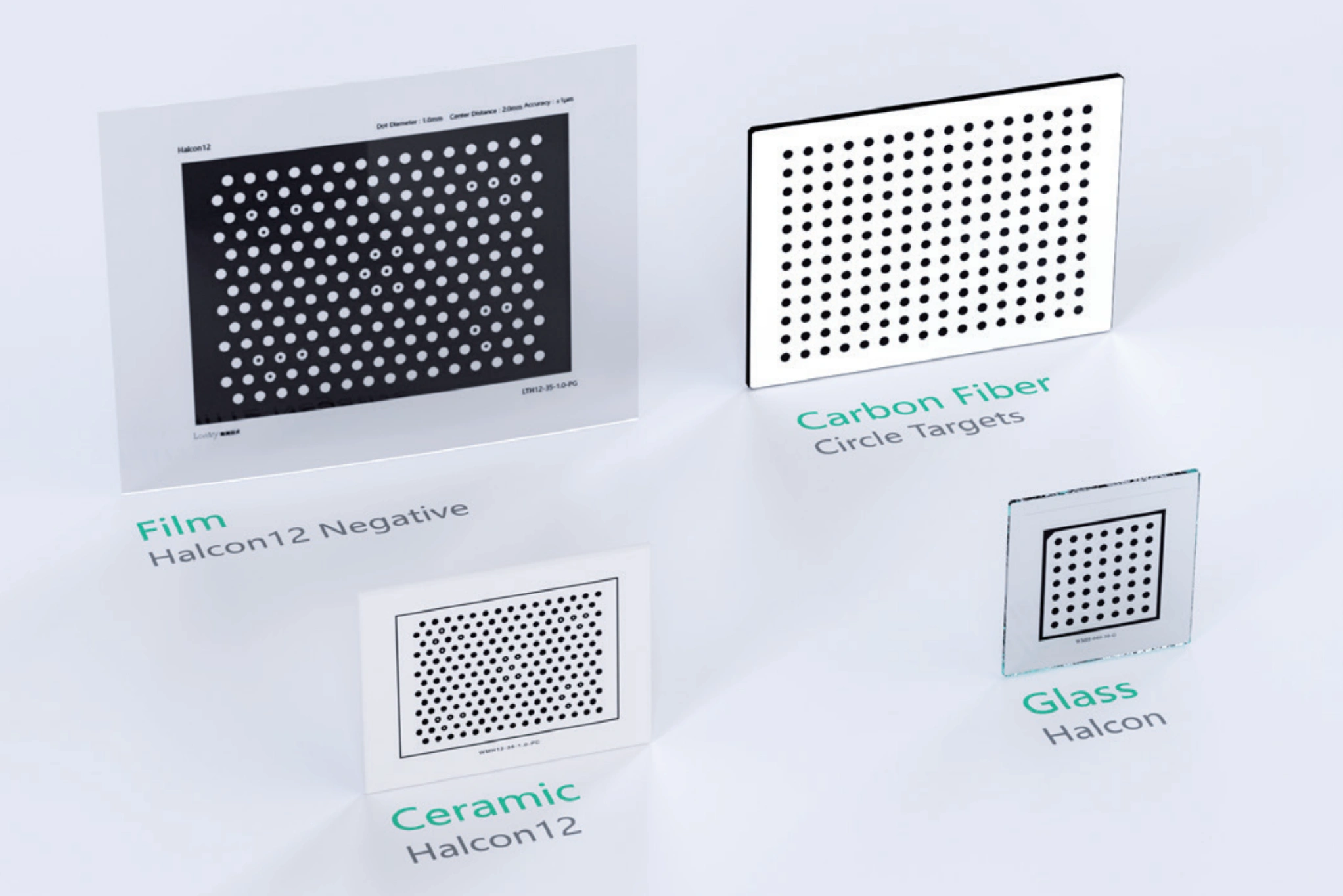

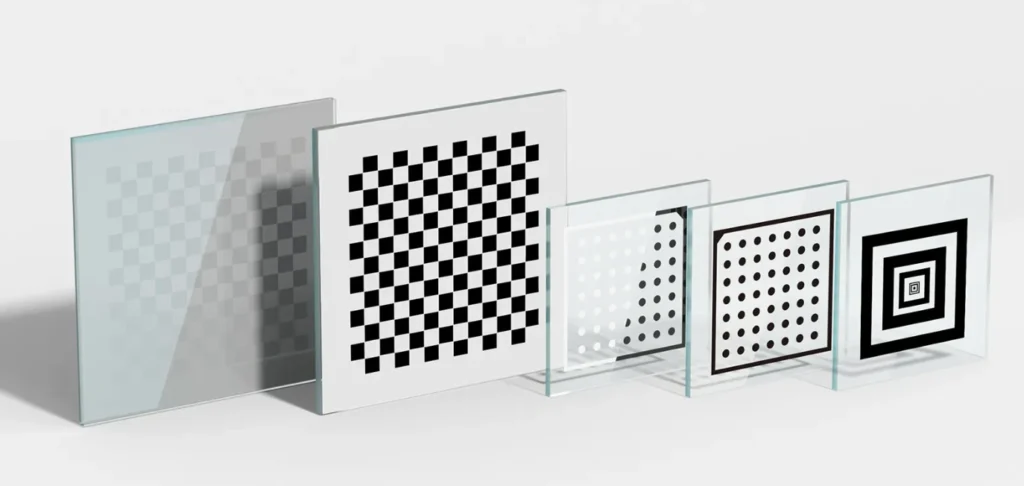

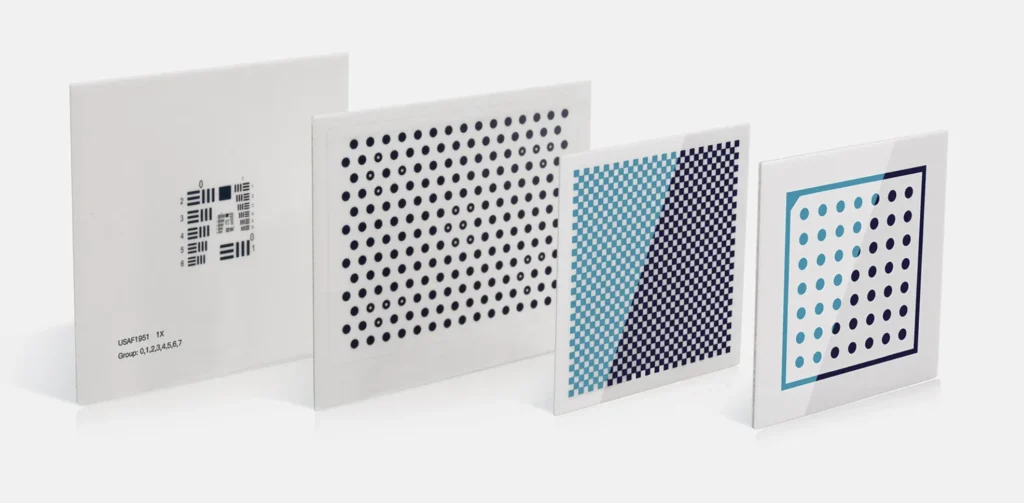

Halcon test targets are specialized calibration tools designed to work with MVTec Halcon and ActiveVision machine vision software. These precision-made targets feature specific patterns of circles or dots arranged in precise geometric configurations that allow vision systems to calibrate camera parameters, correct lens distortion, and establish accurate measurement scales for industrial vision applications.

Keep reading to discover how these targets can improve your vision system’s accuracy, which type is right for your application, and how to get custom targets for unique setups.

How Do Halcon Test Targets Work?

When I first started working with machine vision systems, I was amazed at how a simple-looking pattern could make such a difference in measurement accuracy.

Halcon test targets work through a precise arrangement of high-contrast circular features (either black dots on white background or white dots on black background) that the vision software can easily detect. These circles serve as reference points with known positions and dimensions.

The software looks for these circles in the camera image and compares their apparent positions to their actual positions on the target. From this comparison, the software can calculate:

- Camera intrinsic parameters (like focal length and optical center)

- Lens distortion coefficients

- The exact position and orientation of the camera relative to the target

- Scale factors for converting pixel measurements to real-world units

This calibration process is essential for any application requiring accurate measurements or 3D position determination.

Types of Halcon Calibration Patterns

Not all Halcon targets are created equal. The most common patterns include:

- Standard Circle Grid: Evenly spaced circles in a rectangular arrangement

- Halcon12 Pattern: A specific layout optimized for the Halcon12 software version

- Custom Circle Configurations: Specialized patterns for unique requirements

Each pattern type has specific advantages depending on your application requirements.

Choosing the Right Substrate Material

One thing many engineers overlook is the importance of the substrate material. In my experience, this choice can make or break your calibration accuracy.

Soda Lime Glass

Soda lime glass targets are the gold standard for most applications. They offer:

- Excellent dimensional stability

- High resistance to environmental factors

- Superior flatness (critical for accurate calibration)

- Long-term durability

I typically recommend glass substrates for permanent calibration stations or any application requiring the highest possible accuracy.

Matte Ceramic

Ceramic targets are excellent for harsh industrial environments. Benefits include:

- Exceptional temperature resistance

- Resistance to chemicals and solvents

- Less reflective surface (reduces glare issues)

- High durability against physical damage

If your vision system operates in a challenging environment with temperature fluctuations or chemical exposure, ceramic is often worth the higher cost.

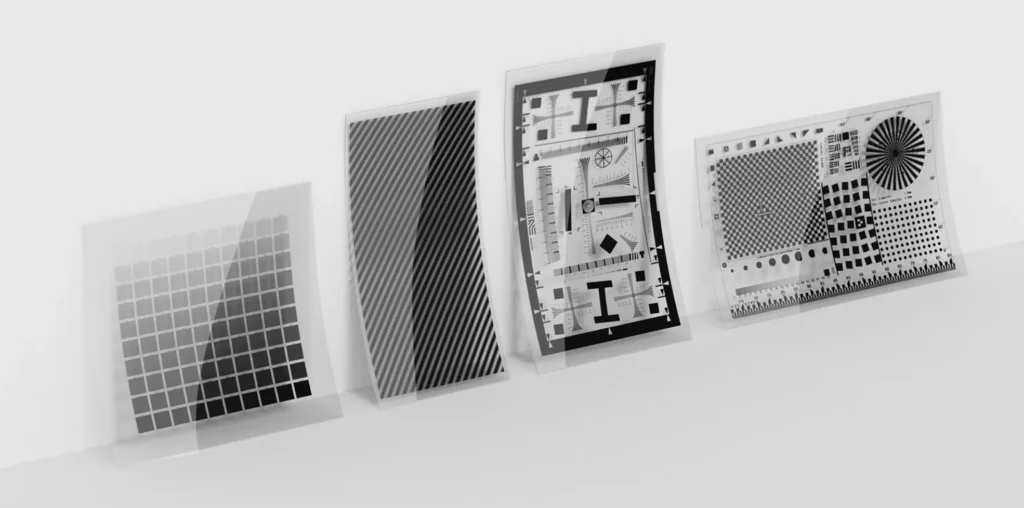

Film Options

Film-based targets offer affordability and flexibility:

- Significantly lower cost than glass or ceramic

- Can be easily applied to various surfaces

- Lightweight and portable

- Available in both rigid and flexible forms

For temporary setups, budget-conscious projects, or applications where the target needs to conform to a curved surface, film targets are an excellent choice.

Standard vs. Custom Halcon Targets

When Standard Targets Are Sufficient

The standard Halcon targets (like models LTH-010-06-G or LTH12-14-0.25-G) work perfectly for many applications. Use standard targets when:

- You’re working at standard working distances

- Your field of view requirements are typical

- You’re using common camera resolutions

- You need quick delivery (usually in stock)

| Model NO. | Product | Substrate Material | Standard Size | Pattern | Accuracy |

| LTH-010-06-G | Halcon | Soda Lime Glass | 10×10 mm | Circle Diameter: 0.375mm Matrix: 7×7, Positive | ±1μm |

| LTH-045-35-G | Halcon | Soda Lime Glass | 45×45 mm | Circle Diameter: 1.25mm Matrix: 7×7, Positive | ±1μm |

| LTH-060-50-G | Halcon | Soda Lime Glass | 60×60 mm | Circle Diameter: 10mm Matrix: 7×7, Positive | ±1μm |

| LTH12-14-0.25-G | Halcon 12 | Soda Lime Glass | 14×12 mm | Circle Diameter: 0.25mm Matrix: 13×15, Positive | ±1μm |

| LTH12-45-1-G | Halcon 12 | Soda Lime Glass | 45×35 mm | Circle Diameter: 1mm Matrix: 13×15, Positive | ±1μm |

| LTH12-92-5-G | Halcon 12 | Soda Lime Glass | 92x72mm | Circle Diameter:5mm Matrix: 13×15, Positive | ±1μm |

| LT -200-D2-C | Circle Targets | Matte Ceramic | 200×200 mm | Circle Diameter: 2mm Matrix: 48×48, Positive | ±2μm |

| LT -300-D3-C | Circle Targets | Matte Ceramic | 300×300 mm | Circle Diameter: 3mm Matrix: 49×49, Positive | ±2μm |

When to Consider Custom Targets

In my experience, custom targets become necessary when:

- Unusual Working Distances

Extremely close or far working distances may require custom circle sizes

- Limited Field of View

Sometimes you need a more compact target that still provides enough calibration points

- Special Feature Requirements

Some applications benefit from additional finder patterns or reference marks

- Unique Substrate Needs

Special applications might require carbon fiber, photographic paper, or other materials

- Non-Standard Dimensions

When mounting constraints dictate unusual target sizes

Custom targets typically involve a 5-7 business day lead time but can solve challenging calibration problems that standard targets can’t address.

Key Specifications to Consider

When selecting a Halcon target, pay attention to these critical specifications:

Circle Diameter

Circle diameter directly impacts calibration accuracy and the working distance of your system:

- Smaller circles (0.1mm-1mm): Better for close-up, high-resolution applications

- Medium circles (1mm-5mm): Ideal for most general applications

- Larger circles (5mm-10mm): Better for longer working distances or lower resolution cameras

Circle Spacing

The spacing between circles affects how well the software can distinguish individual features:

- Tighter spacing (0.1mm-1mm): Allows more calibration points in a smaller area

- Wider spacing (1mm-10mm): Reduces the chance of feature detection errors

Matrix Size

This refers to the number of circles in each row and column:

- Smaller matrices (7×7): Sufficient for basic calibration

- Medium matrices (13×15): Good balance of calibration accuracy and processing speed

- Larger matrices (25×25 or more): Highest accuracy but requires more processing time

Feature Accuracy

This specification tells you how precisely the circles are positioned on the target:

- ±1μm: Standard precision, suitable for most applications

- ±2μm: Found on larger ceramic targets

- Custom tolerances available for specialized needs

Real-World Applications for Halcon Test Targets

Automotive Component Inspection

In automotive manufacturing, Halcon targets are used to calibrate vision systems that inspect:

- Engine components with tight tolerances

- Safety-critical parts like brake assemblies

- Body panel alignment and gap measurement

These applications typically use glass targets for their stability and precision.

Electronics Manufacturing

Electronics inspection requires extremely precise measurements:

- PCB component placement verification

- Solder joint inspection

- Microscopic defect detection

For these applications, smaller circle diameters (0.25mm-1mm) on glass substrates are typically preferred.

Pharmaceutical Quality Control

In pharmaceutical production, vision systems often inspect:

- Correct pill count and identification

- Package integrity

- Label placement and content verification

These applications benefit from ceramic targets due to their resistance to cleaning chemicals.

General Machine Vision Setup

For general machine vision applications like:

- Robot guidance

- Part orientation detection

- Basic measurement tasks

Standard Halcon targets with 1mm-5mm circle diameters on soda lime glass provide an excellent balance of accuracy and cost.

Maintaining Calibration Accuracy

Even the best calibration target won’t help if you don’t use it properly. Here are some tips I’ve learned over the years:

- Handle with care: Always handle targets by the edges to avoid fingerprints or damage

- Clean properly: Use lint-free cloths and appropriate cleaning solutions

- Store safely: Keep targets in protective cases when not in use

- Recalibrate regularly: Environmental changes can affect calibration

- Control lighting: Consistent, diffuse lighting improves feature detection

- Mount securely: Any movement during calibration will introduce errors

Following these practices will extend the life of your target and ensure consistent calibration results.

Conclusion: Selecting the Right Halcon Test Target

Choosing the right Halcon test target doesn’t have to be complicated. Consider your:

- Working distance and field of view

- Required measurement accuracy

- Environmental conditions

- Budget constraints

For standard applications, off-the-shelf targets like the LTH-010-06-G or LTH12-45-1-G work exceptionally well. For unique requirements, custom targets with specific circle sizes, patterns, and substrates can be manufactured to your exact specifications.

Remember that the quality of your calibration target directly impacts the accuracy of your entire vision system. It’s one component where cutting corners rarely pays off in the long run.