The Problem You Didn’t Know You Had

If you’re testing camera modules, you’re probably wasting space. A lot of space.

I recently visited a smartphone manufacturer in Asia. Their testing floor looked like an aircraft hangar. Why? Because testing camera modules traditionally requires massive distances between the test chart and the camera.

But here’s what most manufacturers don’t realize: there’s a simple solution that can transform your production line overnight.

What Is a Relay Lens (In Plain English)?

A relay lens is an optical system that “relays” an image from one point to another. Think of it like an optical tunnel that transports images without losing quality.

In camera testing, relay lenses work like magic:

- They compress the required testing distance by up to 93%

- They maintain the exact same optical parameters and test results

- They don’t compromise image quality or testing accuracy

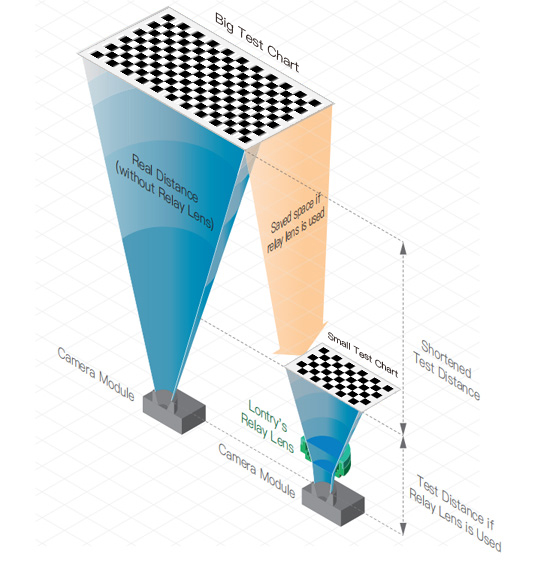

How Relay Lenses Work in Camera Testing

The traditional method requires placing large test charts at considerable distances from camera modules to properly evaluate focus, resolution, and other optical parameters.

A relay lens system changes this by:

- Positioning a smaller test chart at the front focal point of the relay lens

- Transmitting the test chart image through the optical system without distortion

- Presenting this image to the camera module under test at a much shorter working distance

This optical relay creates the same testing conditions as a traditional setup but in a fraction of the space.

Types of Relay Lenses for Different Applications

Visionlabhub offers several relay lens models designed for specific testing scenarios:

- RL Series: Standard relay lenses for general camera module testing

- RLS Series: Specialized for small-format sensors and smartphone cameras

- RLM Series: Customized for automotive camera testing with wide field of view

- RLFD Series: Optimized for facial recognition and depth sensing camera calibration

Each series is designed with specific magnification ratios, working distances, and image quality characteristics to match different testing requirements.

3 Ways Relay Lenses Transform Manufacturing Economics

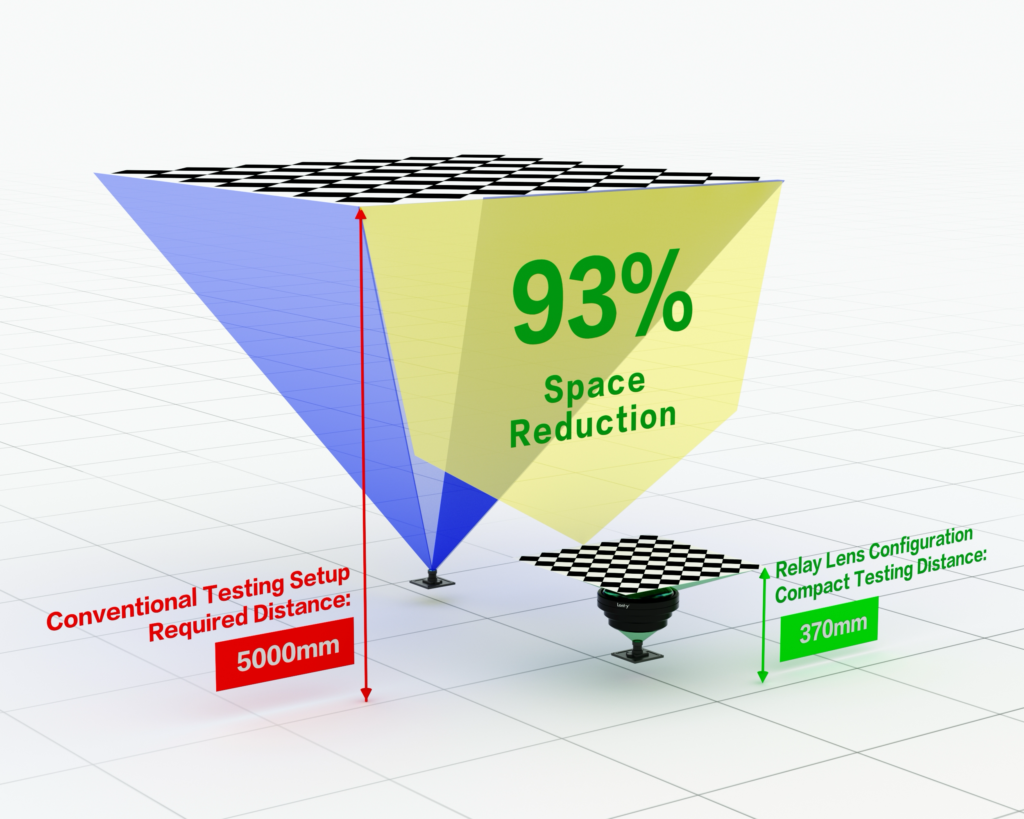

1. Dramatic Space Reduction

Without relay lenses, testing camera modules might require 5 meters (16+ feet) of space between test targets and cameras. With relay lenses, this shrinks to just 370mm (about 14 inches).

What could you do with all that reclaimed factory space?

2. Significant Cost Savings

The savings go beyond just floor space:

- Lower Facility Costs: Less space means lower rent, heating, and cooling expenses

- Smaller Test Equipment: Reduced distance means smaller test charts and fixtures

- Streamlined Operations: More compact testing stations enable better workflow

- Reduced Equipment Expense: Compact test setups require less costly support hardware

One electronics manufacturer calculated savings of $42,000 per month after implementing relay lenses across their testing operations.

3. Improved Quality and Consistency

Testing in a smaller, more controlled environment reduces variables that can affect test results:

- Less air disturbance affecting imaging

- Reduced impact from ambient light variations

- Better protection from dust and contaminants

- More consistent temperature conditions

- Standardized test environments across multiple testing stations

The result? More reliable test data and better quality control.

Key Technical Specifications That Matter

When selecting a relay lens system, pay attention to these critical specifications:

- MTF Performance: Measures the lens’s ability to maintain contrast and resolution

- Distortion: Should be <0.1% for accurate testing results

- Magnification: Typically 1:1 for standard testing or custom ratios for specific applications

- Field of View: Must match or exceed the camera module’s angular field

- Working Distance: The practical space required between components

Visionlabhub’s relay lenses maintain MTF performance above 0.5 at 100 lp/mm, ensuring precise testing results across the entire image area.

Who Benefits from Relay Lenses?

Relay lenses are game-changers for anyone testing:

- Smartphone cameras

- Security cameras

- Automotive imaging systems

- Medical imaging devices

- Machine vision systems

- Drone cameras

- Action cameras

- Facial recognition systems

- 3D sensing cameras

If it has a lens and needs testing, a relay lens can probably improve your process.

Integration with Automated Testing Systems

Modern relay lens systems are designed to work seamlessly with automated testing equipment. Visionlabhub’s relay lenses include:

- Standardized mechanical interfaces for easy integration

- Software-compatible operational parameters

- Modular designs for flexible testing setups

- Support for multi-camera simultaneous testing

This compatibility makes relay lenses ideal for high-volume production environments where testing efficiency directly impacts throughput.

Real-World Example: How One Manufacturer Reclaimed 200m² of Production Space

A leading smartphone component manufacturer was struggling with space constraints as production demands increased. Their testing area consumed nearly 40% of their production floor.

After implementing relay lenses:

- They reduced testing space requirements by 93%

- Testing throughput increased by 35%

- Quality consistency improved by 22%

- They saved $367,000 annually in facility costs

The operations manager told me: “We were skeptical at first. How could something so simple make such a big difference? But the numbers don’t lie. This technology paid for itself in under three months.”

Common Questions About Relay Lenses

Do relay lenses affect test accuracy?

No. When properly designed and implemented, relay lenses maintain the same optical parameters and accuracy as traditional testing setups. In fact, many manufacturers report improved consistency in results due to the more controlled environment.

How difficult is it to integrate relay lenses into existing test procedures?

Most manufacturers can integrate relay lenses with minimal disruption. The basic test procedures remain unchanged – they just happen in a much smaller space. Visionlabhub®️ provides complete integration support including setup guidance and calibration assistance.

Are relay lenses only for high-volume manufacturers?

Not at all. Even small production facilities benefit from space savings and improved test consistency. The initial investment typically pays for itself within months, regardless of production volume.

Can relay lenses be used for infrared and specialized camera testing?

Yes. Specialized relay lenses are available with transmission characteristics optimized for different wavelengths, including NIR and SWIR for testing depth sensing and facial recognition cameras.

The Bottom Line: Why Most Camera Module Manufacturers Are Missing Out

Despite their clear benefits, relay lenses remain surprisingly underutilized in manufacturing. The technology isn’t new, but awareness is low.

This creates a competitive advantage for manufacturers who adopt relay lenses while their competitors continue to waste valuable production space.

If you’re involved in camera module production or testing, relay lenses deserve a serious look. The combination of space savings, cost reduction, and quality improvements creates a compelling business case that few other technologies can match.