Providing the industry standard for accurately measuring and calibrating optical resolution in imaging systems.

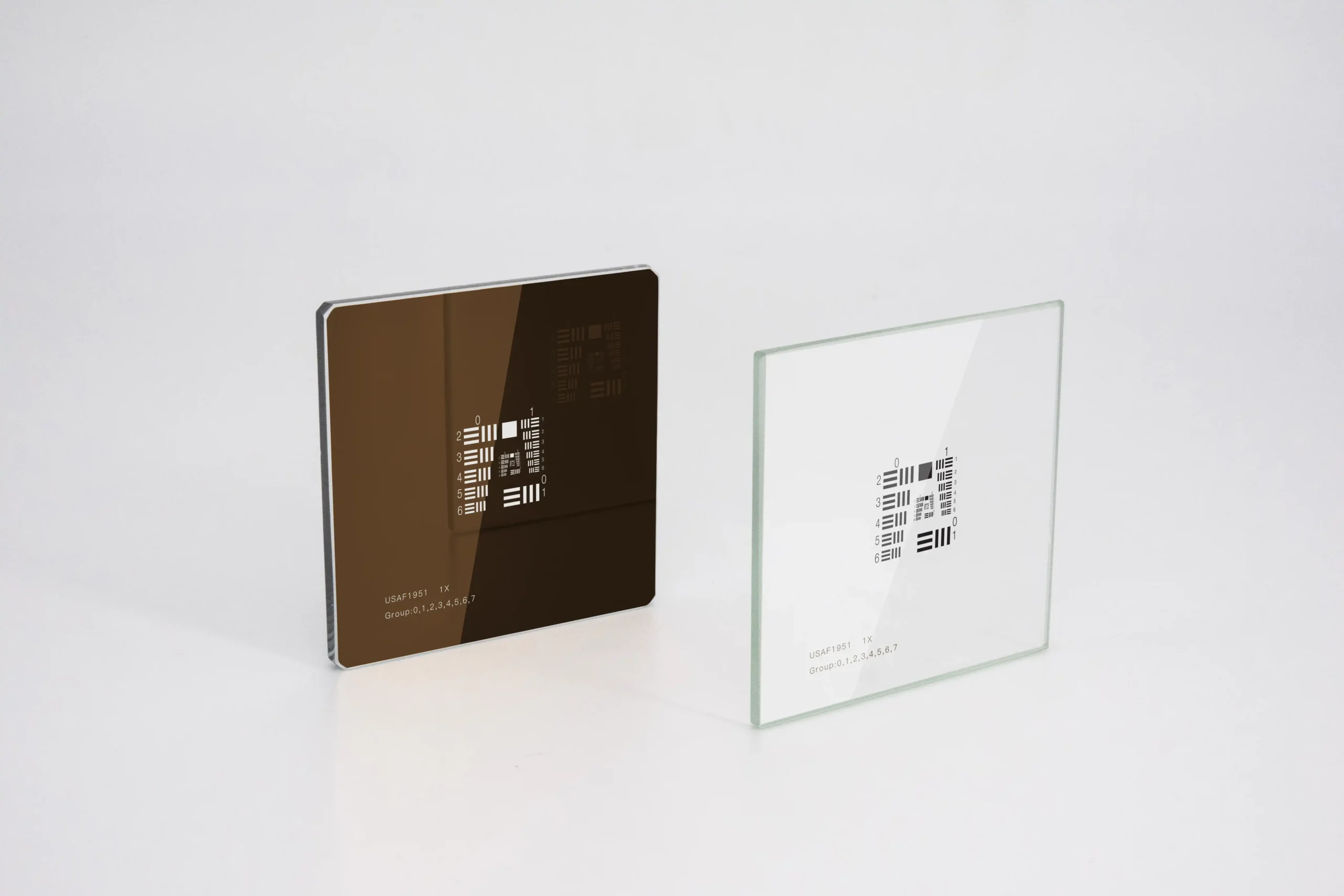

Manufactured with precision chrome patterns on high-quality optical glass, these targets offer exceptional durability and contrast for reliable, repeatable resolution measurements across a wide range of applications.

Each target features the classic USAF1951 pattern with precisely defined groups and elements for standardized evaluation of lenses, cameras, microscopes, and machine vision systems.

$118.00

Our USAF1951 test targets are produced using advanced photolithography processes to ensure precise line widths and spacing. The chrome-on-glass construction provides maximum durability and exceptional optical properties, including high contrast and edge definition necessary for accurate resolution measurements.

|

Model

|

Material

|

Coating Type

|

Over size

|

Positive/

Negative

|

Thickness

|

Pattern

|

|

LTU-025-(0-9,1)-PG

|

Quartz Glass

|

Blue Chrome

|

25x25mm/1″

|

Positive

|

1.6mm

|

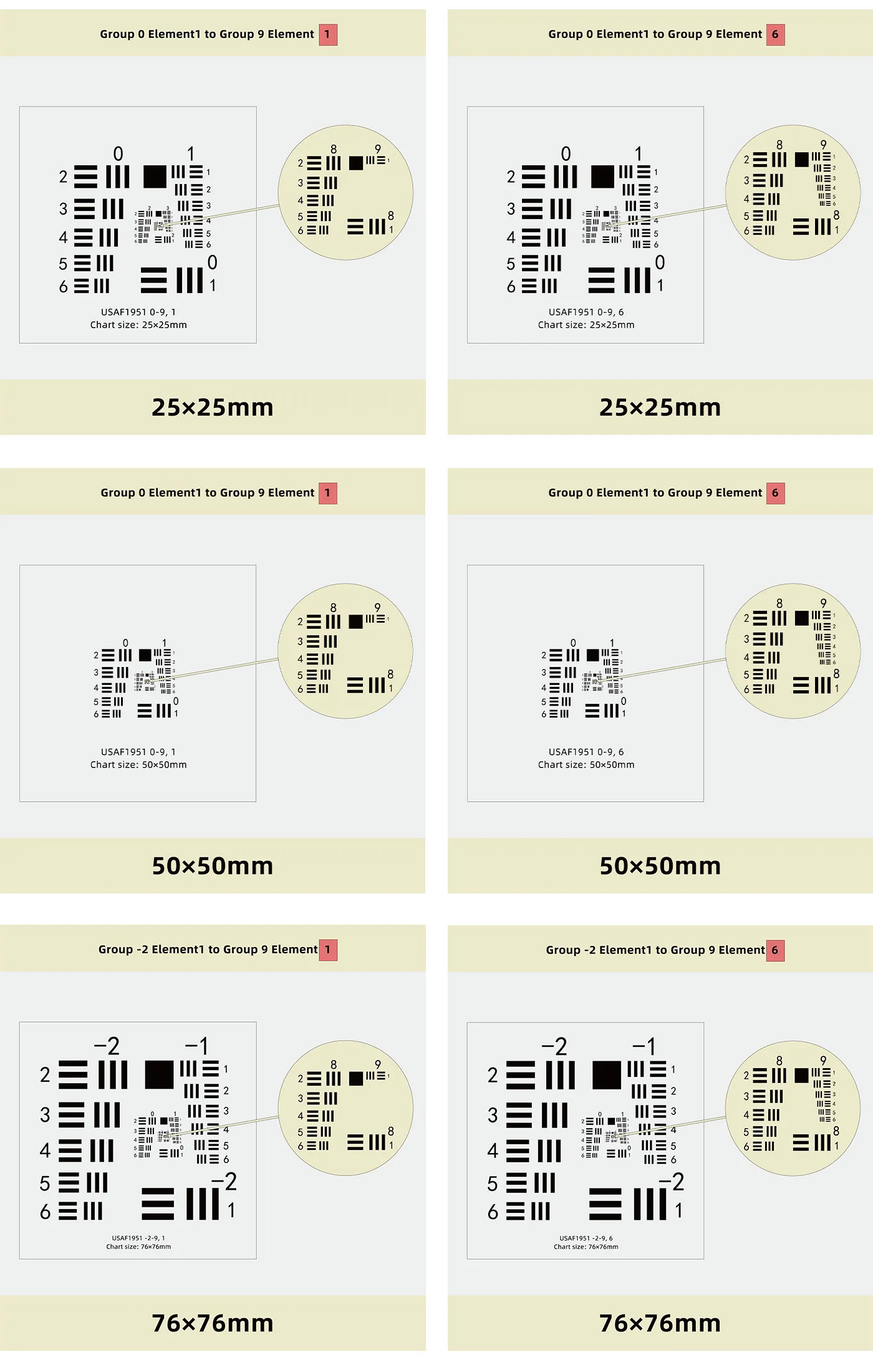

Group 0 Element1 to Group 9 Element1

|

|

LTU-025-(0-9,1)-NG

|

Quartz Glass

|

Blue Chrome

|

25x25mm/1″

|

Negative

|

1.6mm

|

Group 0 Element1 to Group 9 Element1

|

|

LTU-025-(0-9,6)-PG

|

Quartz Glass

|

Blue Chrome

|

25x25mm/1″

|

Positive

|

1.6mm

|

Group 0 Element1 to Group 9 Element1

|

|

LTU-025-(0-9,6)-PG

|

Quartz Glass

|

Blue Chrome

|

25x25mm/1″

|

Negative

|

1.6mm

|

Group 0 Element1 to Group 9 Element1

|

|

LTU-050-(0-9,1)-PG

|

Quartz Glass

|

Blue Chrome

|

50x50mm/2″

|

Positive

|

1.6mm

|

Group 0 Element1 to Group 9 Element1

|

|

LTU-050-(0-9,1)-PG

|

Quartz Glass

|

Blue Chrome

|

50x50mm/2″

|

Negative

|

1.6mm

|

Group 0 Element1 to Group 9 Element1

|

|

LTU-050-(0-9,6)-PG

|

Quartz Glass

|

Blue Chrome

|

50x50mm/2″

|

Positive

|

1.6mm

|

Group 0 Element1 to Group 9 Element1

|

|

LTU-050-(0-9,6)-PG

|

Quartz Glass

|

Blue Chrome

|

50x50mm/2″

|

Negative

|

1.6mm

|

Group 0 Element1 to Group 9 Element1

|

|

LTU-076-(-2-9,1)-PG

|

Quartz Glass

|

Blue Chrome

|

76x76mm/3″

|

Positive

|

1.6mm

|

Group -2 Element1 to Group 9 Element1

|

|

LTU-076-(-2-9,1)-PG

|

Quartz Glass

|

Blue Chrome

|

76x76mm/3″

|

Negative

|

1.6mm

|

Group -2 Element1 to Group 9 Element1

|

|

LTU-076-(-2-9,6)-PG

|

Quartz Glass

|

Blue Chrome

|

76x76mm/3″

|

Positive

|

1.6mm

|

Group -2 Element1 to Group 9 Element1

|

|

LTU-076-(-2-9,6)-PG

|

Quartz Glass

|

Blue Chrome

|

76x76mm/3″

|

Negative

|

1.6mm

|

Group -2 Element1 to Group 9 Element1

|

The USAF1951 pattern consists of groups of three horizontal and three vertical bars, with each group containing six elements. Each successive element is approximately 12% smaller than the previous (factor of 2^(1/6)), and each successive group is half the size of the previous group. This standardized progression allows for precise resolution measurements across a wide range of optical systems.

| Product Specification | ||||||||

| Pattern Info | Substrate Material Info | |||||||

| Production Process | Laser Writing | Substrate Material of Glass |

Quartz Glass (Fused Silica) | |||||

| Minimum Line/space | 1μm / 0.55μm | Transmission (@550nm) |

>95% | |||||

| Feature Accuracy & Avarage Accuracy |

±1μm | Thermal Expansion Coeff (20-200 ℃) |

<5.0×10⁻⁷/K | |||||

| Coating Type | Blue Chrome (Low Reflective) | Expansion Ratio (20-200 ℃) |

0.00006%(0.6μm/℃ of 1m) | |||||

| Reflectivity | < 13.4% @550nm | Surface Flatness | <0.55μm (Dimension<50mm) | |||||

| < 1.8% @650nm | <2μm (Dimension<100mm) | |||||||

| < 2.67% @750nm | <5μm (Dimension>100mm) | |||||||

| Coating Thickness | 120nm (±0.20nm) | Surface Roughness | <0.025μm | |||||

| Optical Density OD | >4.5 | Thickness | 1.6mm (±0.3mm) | |||||

| White Background | Minimum Line/space: 10μm, Thickness: 40μm (White & Smooth Coating on the Back Side) |

MIN / MAX Overall Size |

Min: 4x4mm;

Max: 800x960mm |

|||||

| Positive / Negative |

|

Target Shape | Square | |||||

| Number of line pairs per millimeter in USAF Resolving Power Test Target 1951 | ||||||||||||

| Group Number | ||||||||||||

| Element | -2 | -1 | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 1 | 0.250 | 0.500 | 1.00 | 2.00 | 4.00 | 8.00 | 16.00 | 32.0 | 64.0 | 128.0 | 256.0 | 512.0 |

| 2 | 0.281 | 0.561 | 1.12 | 2.24 | 4.49 | 8.98 | 17.96 | 35.9 | 71.8 | 143.7 | 287.4 | 574.7 |

| 3 | 0.315 | 0.630 | 1.26 | 2.52 | 5.04 | 10.08 | 20.16 | 40.3 | 80.6 | 161.3 | 322.5 | 645.1 |

| 4 | 0.354 | 0.707 | 1.41 | 2.83 | 5.66 | 11.31 | 22.63 | 45.3 | 90.5 | 181.0 | 362.0 | 724.1 |

| 5 | 0.397 | 0.794 | 1.59 | 3.17 | 6.35 | 12.70 | 25.40 | 50.8 | 101.6 | 203.2 | 406.4 | 812.7 |

| 6 | 0.445 | 0.891 | 1.78 | 3.56 | 7.13 | 14.25 | 28.51 | 57.0 | 114.0 | 228.1 | 456.1 | 912.3 |

| Width of a line in micrometers in USAF Resolving Power Test Target 1951 | ||||||||||||

| Group Number | ||||||||||||

| Element | -2 | -1 | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 1 | 2000.00 | 1000.00 | 500.00 | 250.00 | 125.00 | 62.50 | 31.25 | 15.63 | 7.81 | 3.91 | 1.95 | 0.98 |

| 2 | 1781.80 | 890.90 | 445.45 | 222.72 | 111.36 | 55.68 | 27.84 | 13.92 | 6.96 | 3.48 | 1.74 | 0.87 |

| 3 | 1587.40 | 793.70 | 396.85 | 198.43 | 99.21 | 49.61 | 24.80 | 12.40 | 6.20 | 3.10 | 1.55 | 0.78 |

| 4 | 1414.21 | 707.11 | 353.55 | 176.78 | 88.39 | 44.19 | 22.10 | 11.05 | 5.52 | 2.76 | 1.38 | 0.69 |

| 5 | 1259.92 | 629.96 | 314.98 | 157.49 | 78.75 | 39.37 | 19.69 | 9.84 | 4.92 | 2.46 | 1.23 | 0.62 |

| 6 | 1122.46 | 561.23 | 280.62 | 140.31 | 70.15 | 35.08 | 17.54 | 8.77 | 4.38 | 2.19 | 1.10 | 0.55 |

Each test target undergoes rigorous inspection to verify pattern accuracy, optical density, and substrate quality. Our manufacturing process maintains tight tolerances, ensuring consistent performance across production batches. Each target is delivered with a calibration certificate confirming pattern accuracy and traceability.

Summarize your business so the visitor can learn about your offerings from any page on your website.

2025 © All Rights Reserved.

Click to Chat

Typically replies within minutes

Hello, this is Carlos from VisionLabHub, how can I assist you today?

WhatsApp Us

🟢 Online | Privacy policy

Click to Chat Now