In industrial automation and machine vision systems, cables often face extreme conditions that standard cables simply can’t handle. When cameras and sensors need to move constantly, ordinary cables fail quickly. This is where high flex cables become essential—but what exactly are they, and why do they matter?

What is a High Flex Cable?

A high flex cable is a specialized cable designed to withstand repeated bending and flexing without failure. These cables feature finely stranded conductors, special jacket materials, and reinforced construction that allows them to endure millions of flex cycles in dynamic applications where constant movement occurs, such as robotic arms, drag chains, and automated inspection systems.

Unlike standard cables that might last for just thousands of movement cycles, high flex cables are tested to withstand millions of flex cycles without breaking or degrading. This makes them essential in manufacturing environments where downtime due to cable failure can cost thousands of dollars per hour.

What is the Difference Between Flex Cable and Wire?

The main difference between a flex cable and a wire is that a flex cable contains multiple conductors bundled together within a specialized jacket designed for repeated movement, while a wire typically refers to a single conductor. Flex cables are engineered systems with specific bend radius ratings, strain relief, and shielding layers to maintain signal integrity during movement, whereas individual wires are simpler components not designed for complex motion applications.

Standard wires may be flexible enough for installation but aren’t made to withstand repeated movement. Even when bundled, regular wires will quickly develop conductor fatigue and break. High flex cables, by contrast, use specialized construction methods with ultra-fine strands and advanced materials specifically designed for continuous motion environments.

Why High Flex Cables Are Critical for Industrial Cameras

In machine vision systems, cameras frequently need to:

- Move along inspection lines

- Rotate to capture different angles

- Mount on robotic arms

- Operate in drag chains

When standard cables are used in these dynamic applications, they typically fail within weeks or months, causing:

- System downtime: Production stops while cables are replaced

- Inconsistent imaging: Intermittent connections before complete failure

- Data loss: Signal degradation leading to missed inspections

- Safety hazards: Exposed conductors from broken cable jackets

High flex cables solve these problems by providing reliable connections even in the most demanding motion applications.

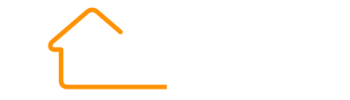

Key Components of a Quality High Flex Cable

1. Conductor Design

The foundation of any high flex cable is the conductor design:

- Ultra-fine stranding: Uses many thin copper strands instead of fewer thick ones

- Bunch stranding: Special arrangement of wire bundles to distribute flex stress

- Strand treatment: Special plating to prevent oxidation and reduce friction

This construction allows each tiny strand to move independently during flexing, preventing the work hardening and breakage that occurs in standard cables.

2. Insulation Materials

The materials surrounding the conductors are equally important:

- TPE (Thermoplastic Elastomer): Maintains flexibility in extreme temperatures

- PUR (Polyurethane): Offers excellent abrasion resistance

- Special TPEs: Engineered for specific environmental conditions

These materials stay flexible even after millions of cycles, unlike PVC which hardens over time and eventually cracks.

3. Shielding Construction

For vision applications, signal integrity is critical:

- Braided shields: Flexible copper braiding that can bend repeatedly

- Foil shields: Often used in conjunction with braiding for complete coverage

- Drain wires: Specially placed to maintain shield continuity during movement

Proper shielding prevents electromagnetic interference (EMI) from affecting sensitive camera signals, ensuring consistent image quality.

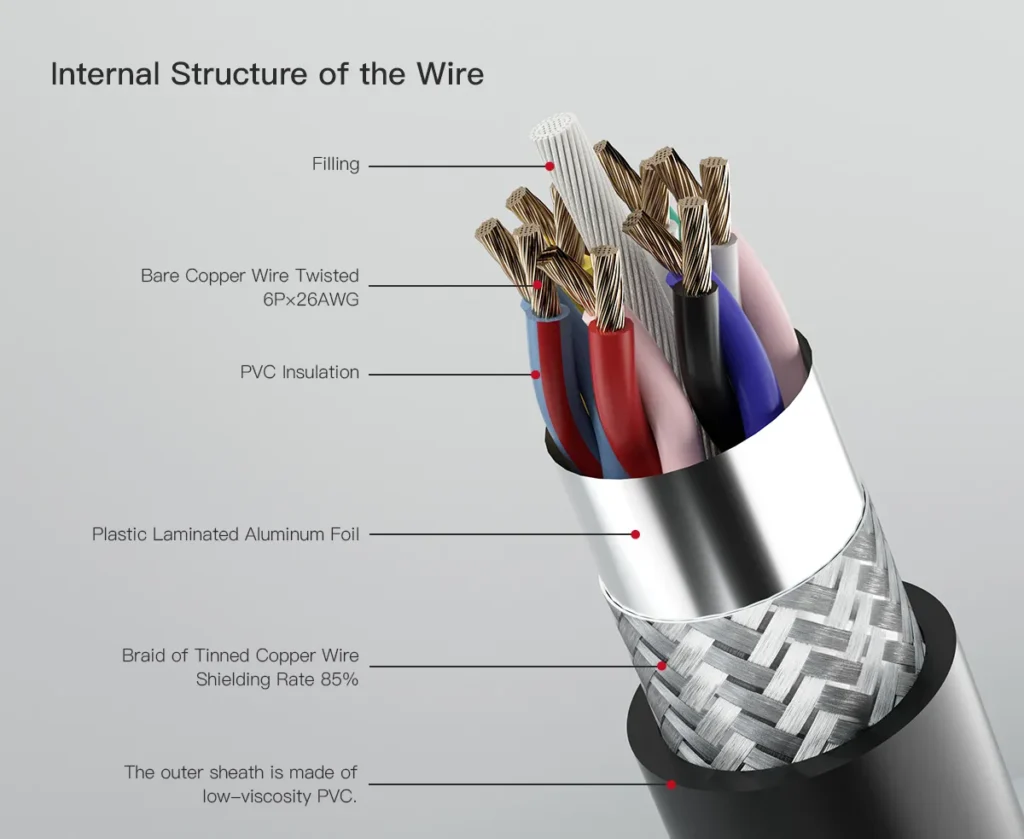

4. Jacketing Technology

The outer jacket must protect the cable while remaining flexible:

- Abrasion-resistant compounds: Prevent wear from rubbing against other components

- Oil-resistant formulations: Maintain integrity when exposed to industrial fluids

- Low-friction materials: Reduce drag and wear in cable tracks

Testing and Performance Ratings for High Flex Cables

When selecting high flex cables, understanding their performance ratings is crucial:

Flex Life Testing

Quality high flex cables undergo rigorous testing:

- Torsion testing: Cables are twisted through specific angles for millions of cycles

- Bend testing: Cables are bent at specific radii while moving back and forth

- Drag chain simulation: Real-world usage patterns are replicated for extended periods

The resulting cycle ratings tell you how long a cable can be expected to last in your application.

Bend Radius Specifications

Every high flex cable has minimum bend radius ratings:

- Static bend radius: How tightly the cable can be bent during installation

- Dynamic bend radius: The minimum bend allowed during movement (typically larger)

For example, a high-quality 5mm diameter high flex cable might specify:

- Static bend radius: 4× diameter (20mm)

- Dynamic bend radius: 8× diameter (40mm)

Exceeding these specifications dramatically reduces cable life.

Real-World Applications of High Flex Cables in Vision Systems

Production Line Inspection Cameras

In production environments, cameras often move to inspect different parts or products:

- Sliding along linear rails to capture various sections of large products

- Moving up and down to accommodate different product heights

- Rotating to capture multiple angles of complex parts

High flex cables ensure these cameras maintain reliable connections through hundreds of thousands of movement cycles.

Robotic Vision Systems

Robot-mounted cameras face even more demanding conditions:

- Multi-axis movement with complex bending patterns

- Acceleration forces that stress cable components

- Torsional movement (twisting) along with bending

Special robot-rated high flex cables incorporate additional strain relief and construction techniques to handle these extreme conditions.

Collaborative Robots (Cobots)

With cobots becoming more common, their vision systems require:

- Cables that can withstand frequent reconfiguration

- Higher cycle counts due to faster movements

- Safer jacketing materials for human interaction

Choosing the Right High Flex Cable for Your Vision System

Step 1: Understand Your Movement Requirements

Before selecting a cable, evaluate:

- Type of movement: Linear, torsional, or combined

- Speed of movement: Faster movements create more stress

- Cycle frequency: How often the movement occurs

- Environmental factors: Temperature, exposure to oils/chemicals, abrasion risk

Step 2: Match Connector Types to Your Equipment

For vision systems, common connector options include:

- Camera-side connectors: M12, Hirose HR10, Custom 12-pin

- Control-side options: Open leads, D-Sub, Industrial Ethernet

- Combined solutions: Power and signal in one cable vs. separate cables

Step 3: Consider Signal Requirements

Different vision applications have varying signal needs:

- GigE Vision: Requires Category 5e or better Ethernet construction

- USB3 Vision: Needs controlled impedance and specialized shielding

- Camera Link: Demands precise conductor spacing and extensive shielding

- Power requirements: Adequate gauge sizing for voltage drop over distance

Installation Best Practices for High Flex Cables

Even the best high flex cables will fail prematurely if improperly installed:

Proper Strain Relief

- Install strain relief at both cable ends

- Ensure the first point of flexing is not directly at the connector

- Use proper cable glands where cables enter enclosures

Drag Chain Considerations

When using cables in drag chains:

- Arrange cables so they move freely without crossing

- Leave sufficient space (typically 10-20% of chain interior)

- Use separator elements to prevent cable-to-cable abrasion

- Ensure chains are properly aligned to prevent binding

Climate Considerations

Temperature affects cable performance:

- Cold environments make cables stiffer and more prone to damage

- Hot environments can soften jacketing materials

- Humidity can affect shielding performance

Select cables rated for your specific environmental conditions.

Maintenance and Replacement Planning

Predictive Maintenance

To prevent unexpected failures:

- Visually inspect cables periodically for jacket wear

- Implement scheduled replacement before failure

- Monitor system performance for early warning signs

Total Cost of Ownership

When evaluating cable options, consider:

- Initial purchase cost vs. replacement frequency

- Downtime costs from cable failure

- Installation labor for replacement

- Potential damage to connected equipment

A higher-quality cable with longer flex life often provides significantly lower total cost of ownership.

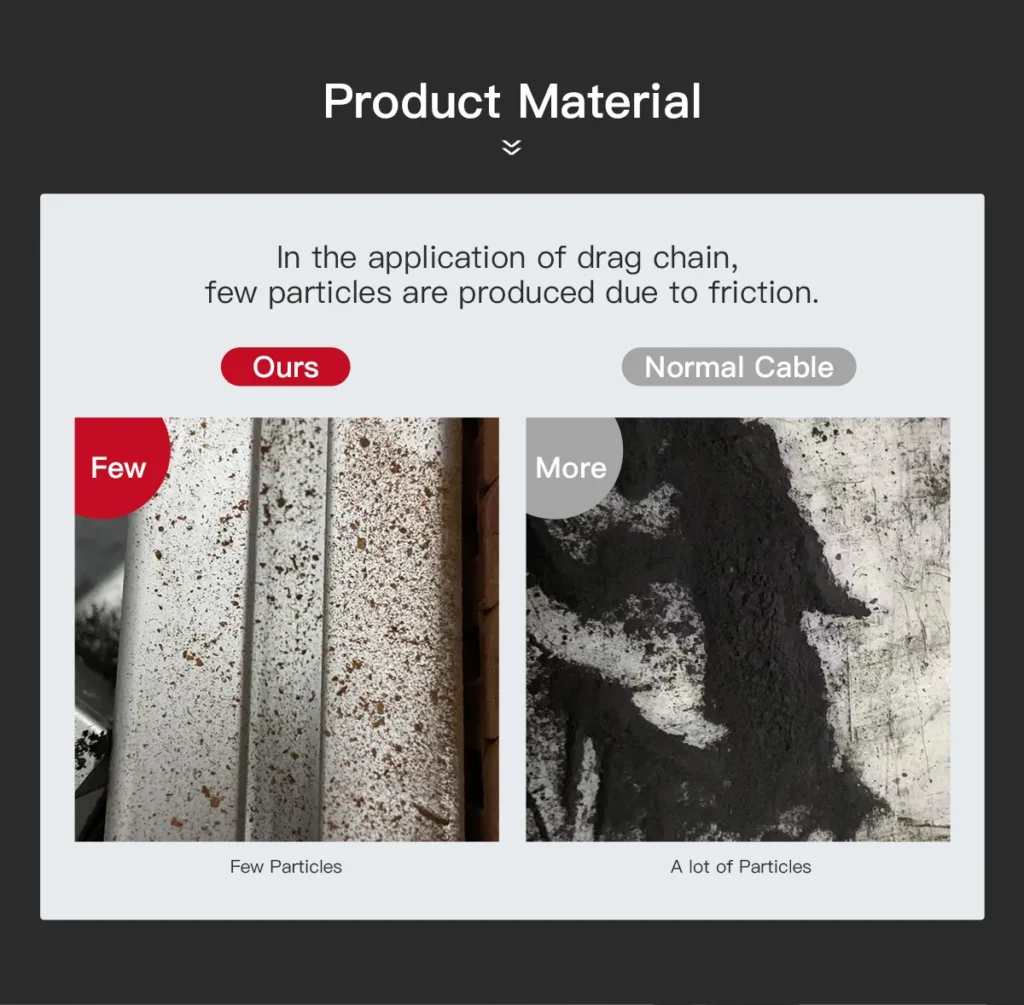

The VisionLabHub Advantage: 12-Pin Camera High Flex Cables

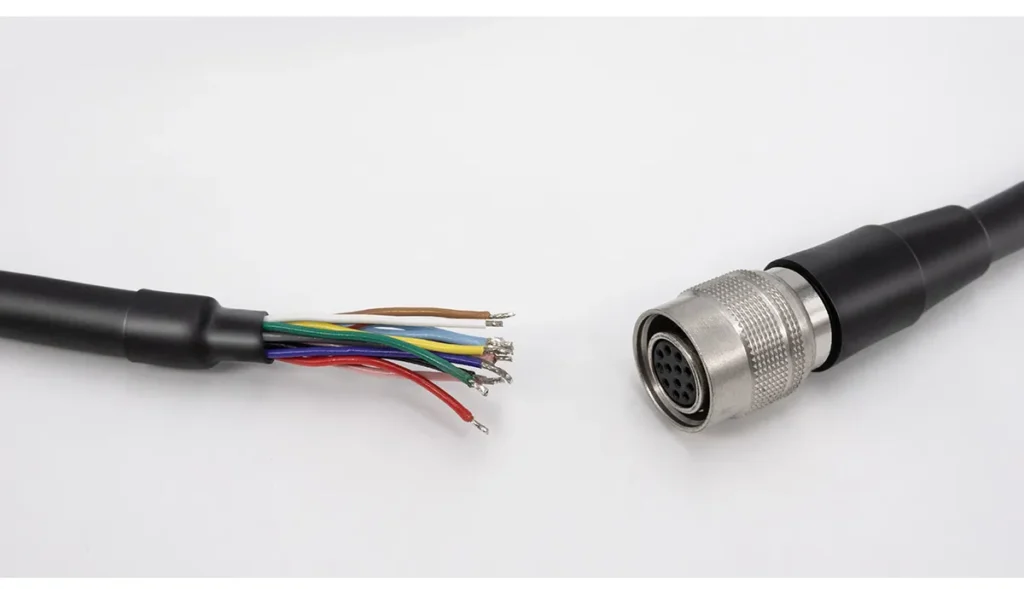

VisionLabHub’s 12-Pin Female to Open Trigger I/O Camera Power High Flex Cables are specifically engineered for industrial camera applications requiring continuous movement:

Superior Construction Features

- 20+ million flex cycle rating: Tested at 9× cable diameter bend radius

- Double shielding protection: Braided shield plus foil for maximum EMI immunity

- Industrial-grade materials: VW-1 flame rating and oil-resistant jacketing

- Color-coded conductors: For easy identification and installation

- Custom length options: Available in 2m, 5m, 10m, and custom lengths

Application Versatility

The open-end design provides maximum flexibility for system integration:

- Connect to custom trigger systems

- Interface directly with PLCs

- Customize power connections

- Implement specialized I/O configurations

Compatible Camera Systems

These high flex cables are compatible with major industrial camera systems using 12-pin interfaces, including:

- Leading machine vision cameras

- Industrial inspection systems

- Robotics vision platforms

- Quality control imaging systems

Conclusion: Investing in Reliability

While standard cables might seem adequate and less expensive initially, the cost of downtime and replacement quickly outweighs any short-term savings.

High flex cables are an essential investment in system reliability, especially in modern high-speed automation environments where every minute of downtime has significant financial impact.

By choosing properly specified high flex cables for your machine vision applications, you ensure more consistent operation, reduce maintenance costs, and ultimately achieve better performance from your vision systems.

Looking for high-quality high flex cables for your industrial camera applications? Explore VisionLabHub’s selection of specialized cables designed for demanding machine vision environments.