Diamond Cutting Lenses: Positioning vs Precision Measurement

This comprehensive guide explores the critical role of FA (Factory Automation) and telecentric lenses in modern diamond cutting operations. The article distinguishes between two essential optical applications: FA lenses for positioning and workflow management, and telecentric lenses for precision measurement and cutting guidance.

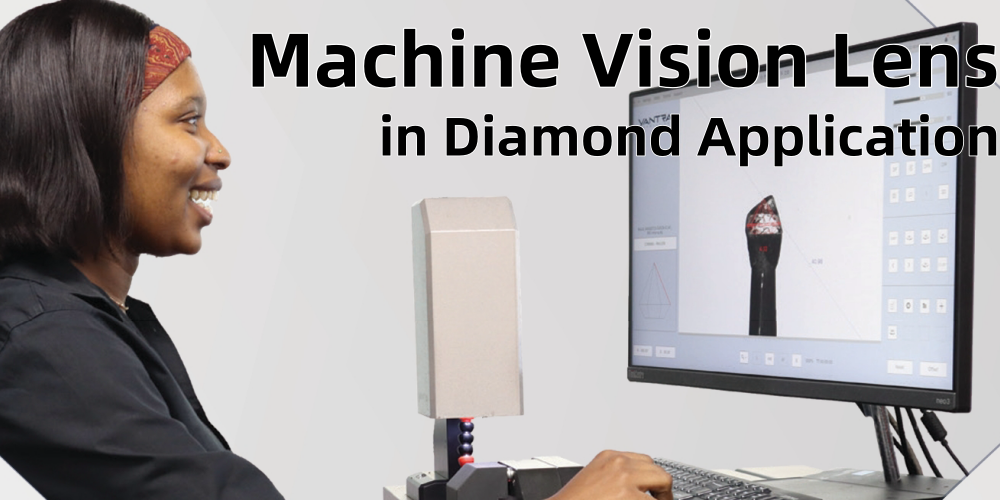

What Are Custom Test Targets? Complete Guide for Imaging Systems

Custom test targets are specialized charts designed for specific imaging applications to evaluate performance or calibrate settings. They measure resolution, distortion, color accuracy, and other parameters. Unlike standard targets, custom designs match exact application requirements, materials, and environmental conditions for more accurate system validation.

GIGE vs. USB3 Camera Cables: Which is Best for Your Vision System?

GigE Vision offers 1 Gbps speed with 100m cable reach, ideal for multi-camera industrial systems. USB3 Vision provides 5 Gbps speed but limits cables to 5m, best for single-camera high-speed applications. Choice depends on camera count, distance, environment, and scalability needs.

Machine Vision Cable Failures: Prevention & Troubleshooting Guide

Machine vision cables fail at the worst possible times. I’ve seen production lines shut down for hours because a $50 cable broke, costing companies thousands in lost productivity and missed deadlines. The good news? Most cable failures are completely preventable when you know what to look for and how to protect your systems. What Causes […]

Best Cables for Machine Vision in Automotive Manufacturing

Automotive vision systems require specialized cables for each production zone: weld-resistant cables for body shops, chemical-resistant jackets for paint inspection, oil-proof designs for powertrain assembly, and high-flex cables for final quality control—all engineered to withstand 24/7 production demands.

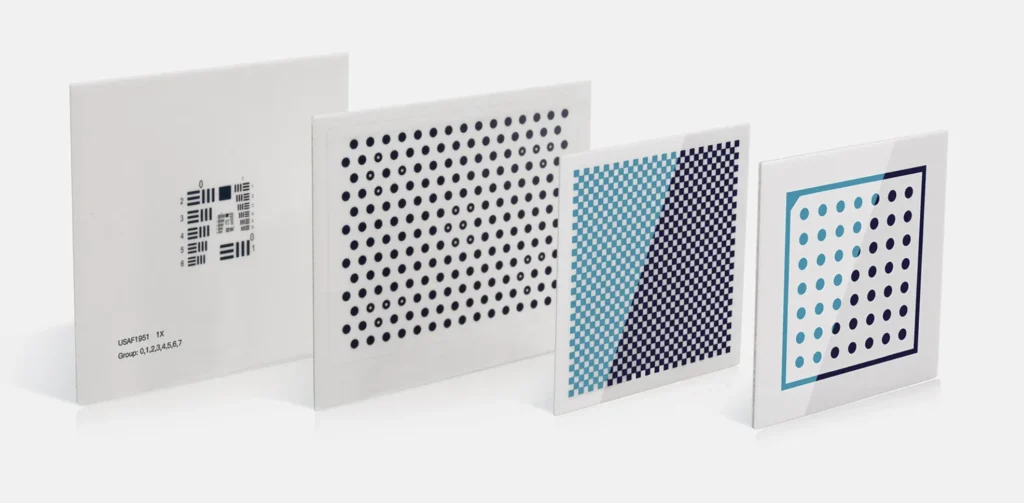

What Is AOI For Pharmaceutical Ampoule Inspection?

Automated Optical Inspection (AOI) for pharmaceutical ampoules uses specialized cameras, lighting, and software to detect critical defects including dimensions, wall thickness, cracks, contamination, and print quality at production speeds of up to 400 units per minute with 98-99% accuracy.

Hệ thống kiểm tra hình ảnh thông minh SVI4K-0745 không cần thiết lập máy tính | VisionLabHub

Hệ thống kiểm tra hình ảnh thông minh hoàn chỉnh, sẵn sàng để sử dụng ngay. Dễ dàng thiết lập và sử dụng, tiết kiệm thời gian và công sức. Giải pháp kiểm tra hình ảnh hiệu quả về chi phí, thân thiện với người dùng. Tầm nhìn và sứ mệnh công nghệ Thương hiệu […]

VisionLabHub Celebrates Record-Breaking Q1 with $10 Million in Sales

VisionLabHub reaches $10 million in Q1 sales through collaborative problem-solving and on-site engineering support. Success stems from helping customers implement complete vision solutions rather than just selling components, with 78% of revenue coming from integrated systems across 14 countries.

How to Solve Visual Inspection Challenges: VisionLabHub’s Quality Assurance Approach

This article details VisionLabHub’s systematic approach to solving common visual inspection challenges in manufacturing. It showcases how we deliver custom, high-quality machine vision solutions with remarkably fast turnaround times, even for complex requirements. The post highlights our four-pillar quality assurance process: superior product engineering, comprehensive testing, specialized packaging, and dependable delivery scheduling. These advantages translate to reduced integration time, lower costs, faster time-to-market, and enhanced quality assurance for manufacturers implementing machine vision systems.