High Flex Cables

Reliable High Flex Cable for Continuous-motion Applications

What Is High Flex Cable ?

What Is Cable Flexibility?

Flexibility in cables refers to the physical ability of a cable to bend, twist, or move from its normal position without sustaining damage.

This property is determined by the cable’s construction, including conductor stranding, jacket material, and internal design. High-flexibility cables use finely stranded conductors (often 30+ strands per wire), specialized jacket materials like polyurethane or thermoplastic elastomer, and optimized internal geometries that allow significant bending while maintaining proper electrical performance.

The flexibility of a cable is typically measured by its minimum bend radius—the smallest curve a cable can make without physical or electrical damage. Cables with high flexibility ratings can be bent to much smaller radii (often 5-7x cable diameter) compared to standard cables (typically 8-10x diameter).

What Is Cable Flex Life?

Flex life describes a cable’s ability to withstand repeated bending cycles without failure.

While flexibility measures how far a cable can bend at any given moment, flex life indicates how many times it can perform those movements before breaking. High flex life cables are engineered with special construction techniques including extremely fine copper stranding, specialized core materials to prevent internal abrasion, and reinforced jacket designs that distribute stress evenly during repeated movement. These cables are typically rated for millions of bend cycles, with premium versions exceeding 10 million cycles in standardized testing.

Flex life is crucial for applications where cables are in constant motion, such as robotic arms, drag chains, or moving gantries. Standard cables may work initially but fail rapidly under continuous movement, while properly designed high-flex cables maintain performance through millions of cycles.RetryClaude can make mistakes. Please double-check responses.

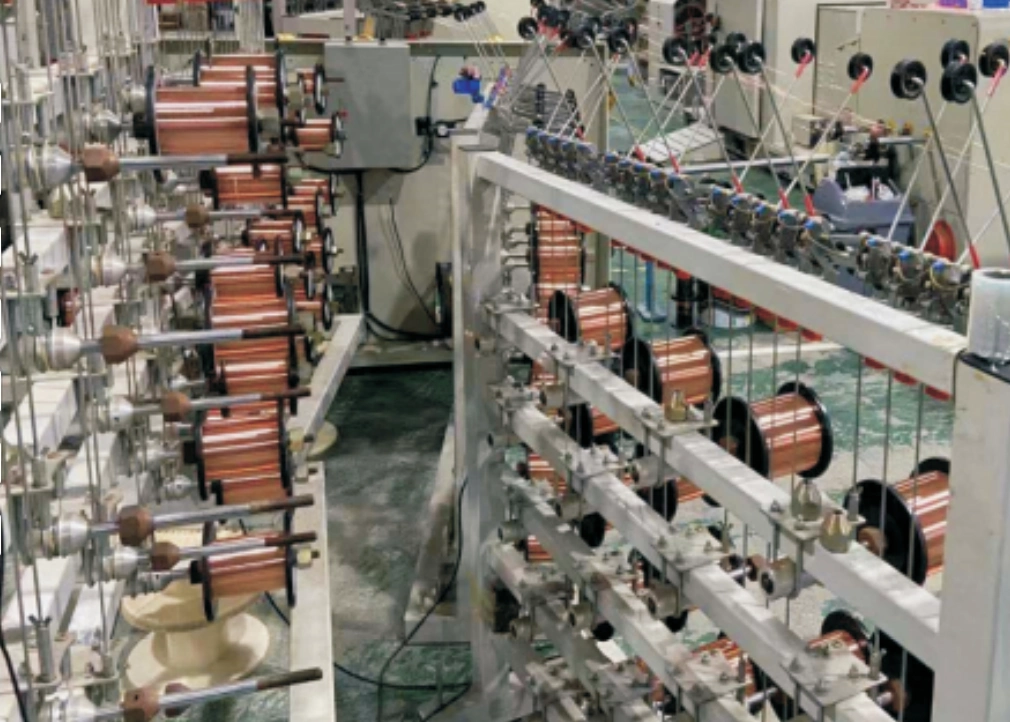

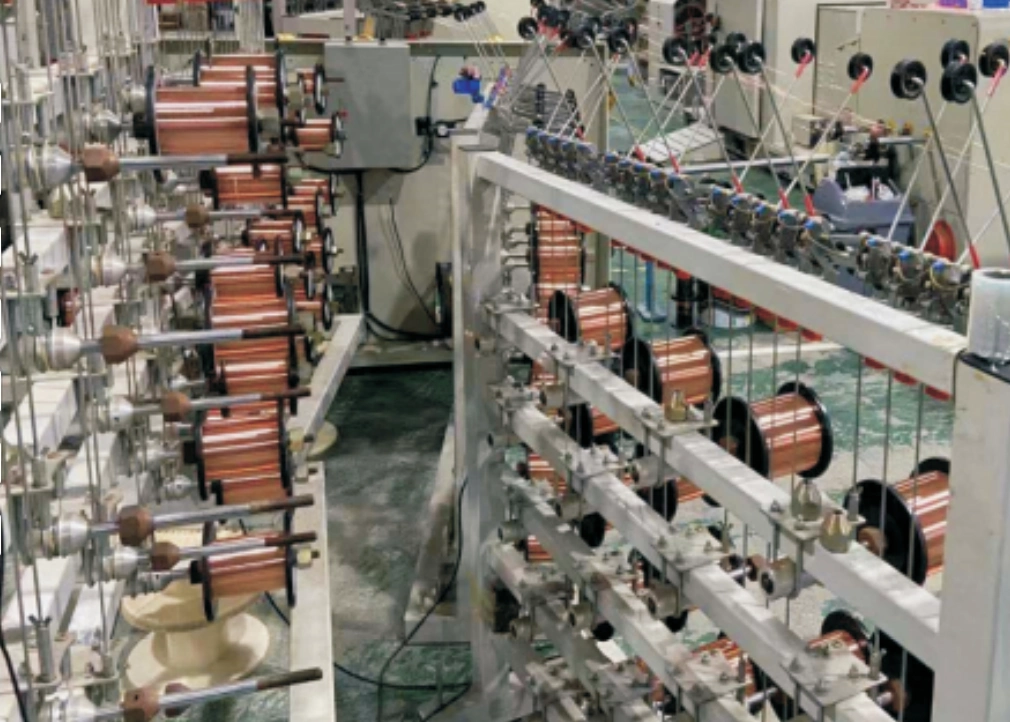

High Flex Cable Manufacturer

As a specialized high-flex cable manufacturer combining Japanese engineering precision with innovative design, we produce mission-critical cables that withstand 20+ million flex cycles in the harshest environments.

Our comprehensive product line includes machine vision cables, robot cables, and industrial data transmission solutions—all manufactured with proprietary techniques in our state-of-the-art facility. With UL certification, RoHS compliance, and trusted by leading brands in the USA, Japan, and South Korea for OEM/ODM services, we deliver custom cable solutions engineered for maximum performance and reliability in your most demanding applications.

VisionLabHub cables are built to withstand continuous bending and twisting motion

Industrial-grade TPE outer jacket cable for factory automation, robotics, and other continuous motion cable applications.

Cut-resistant, industrial-grade TPU cable for factory automation, robotics, and other continuous motion cable applications